The reverse osmosis process has proven to be one of the most efficient and effective technologies for water purification in a wide range of applications. However, as with any system, this process also faces challenges, and one of the most common problems affecting its performance is the clogging of reverse osmosis membranes.

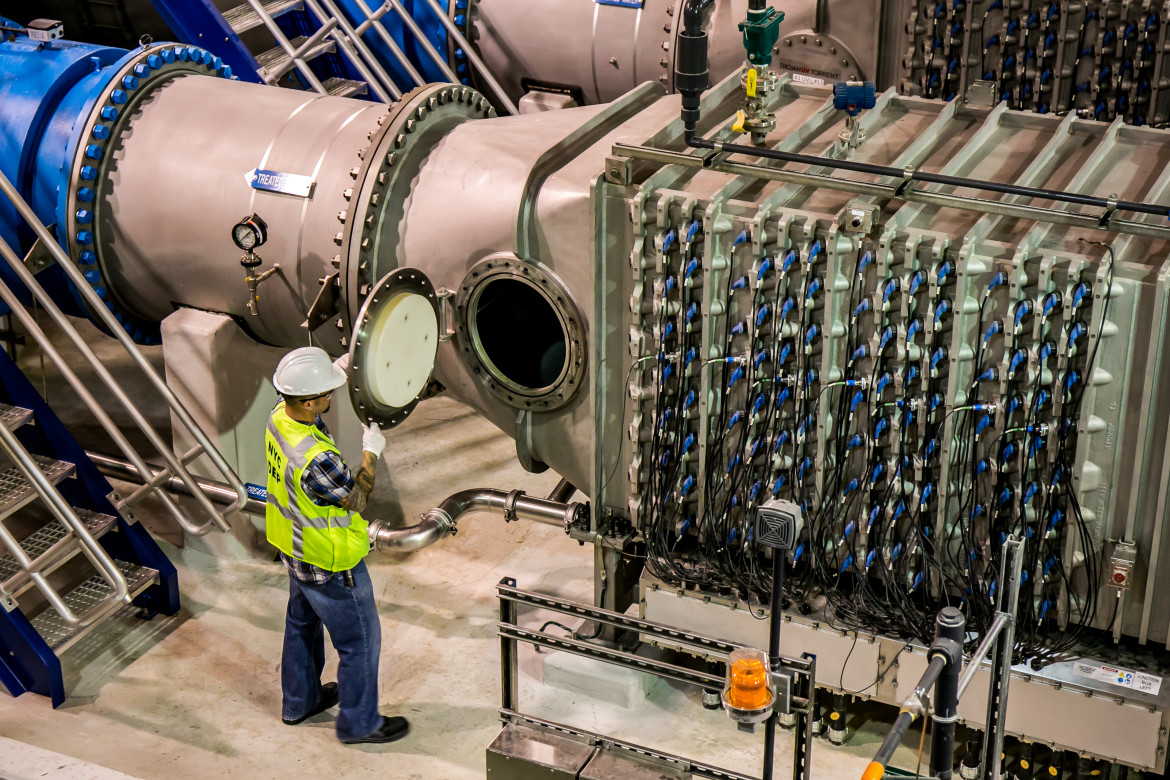

Before addressing the clogging problem, it is essential to understand how the reverse osmosis membrane works. This semi-permeable membrane acts as a barrier that allows water molecules to pass through it while rejecting contaminants and larger particles. In this way, the reverse osmosis process efficiently removes impurities, salts, bacteria and other contaminants present in the water, producing high-quality purified water on the other side of the membrane.

What are the main clogging problems in reverse osmosis membranes?

Membrane clogging can be caused by several reasons, including:

- Contaminants in the feed water: Suspended particles, sediments and bacteria present in the water can accumulate on the membrane surface and reduce its purification capacity.

- Poor or inadequate cleaning: Inadequate maintenance, or lack of proper periodic cleaning of the membrane, can lead to debris accumulation and clogging.

- Operating conditions: Factors such as temperature, pH and water pressure can influence the likelihood of membrane fouling. clogging problems in reverse osmosis membranes

What can we do to mitigate these problems?

Prevention and proper management of membrane clogging are critical to maintaining an efficient reverse osmosis system. Some preventive measures and solutions include:

- Pre-filtration: Use pre-filtration systems (such as pre-treatment using zeolite-based filter media) to remove larger particles and contaminants before the water enters the RO system.

- Proper cleaning schedule: Establish a regular and proper membrane cleaning schedule to remove buildup and prolong the life of the membrane.

- Constant monitoring: Constant monitoring of system performance and produced water quality to identify any clogging problems early.

How does zeolite benefit the care of reverse osmosis membranes?

Pretreatment with zeolite in a reverse osmosis system offers a number of significant benefits that improve overall system performance and efficiency. Zeolite helps keep the reverse osmosis membrane cleaner and free of clogging, which prolongs its life and decreases the need for frequent replacements. Some of the most important benefits are:

- Absorption of heavy metals: Zeolite has ion exchange properties that allow it to absorb and remove heavy metals, such as lead, arsenic, mercury and cadmium, from water. This helps to improve water quality by reducing the presence of hazardous contaminants.

- Removal of certain ions: Zeolite can also remove some unwanted ions, such as ammonium and metal cations, from water, which helps reduce the load on the reverse osmosis membrane and prolongs its life.

- Suspended solids removal: Being a porous material with a high adsorption capacity, zeolite can trap and remove suspended solids present in the water. This prevents these particles from clogging the reverse osmosis membrane, ensuring smoother water flow and preventing early clogging of the system.

- Reduced maintenance: By removing contaminants and suspended solids before the water enters the RO system, zeolite pretreatment reduces the need for frequent system cleaning and maintenance, saving time and resources.

Reverse osmosis filter media and zeolite: an excellent combination.

Zeomedia is the only highly efficient zeolite-based filter media that has been chemically cleaned to optimize quality and performance.

It generates 60% less water and energy wasted in backwashes per year and up to 50% better filtration quality.

Can increase the production capacity of an existing plant by at least 30% or halve the number and size of filters required per project.

More efficient filtration with Zeomedia

In conclusion, reverse osmosis membrane fouling is a common challenge, but with proper maintenance and the implementation of pretreatment using Zeomedia, it is possible to maintain an efficient and reliable water purification system.

If you are interested in learning more about how this technology can help you or how you can start implementing it in your plant, do not hesitate tocontact us.