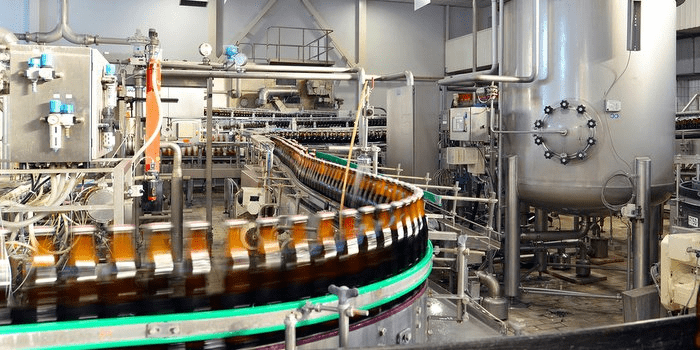

The brewing industry has undergone significant changes in recent years, with a notable shift towards the consumption of mixed beer drinks rather than traditional beer. Water management in the brewing industry

This transition has been driven by a growing variety of beer-mixed drinks and rising raw material prices, which result in steadily increasing beer prices.

Additionally, the industry has witnessed a surge in microbreweries, particularly in urban areas, where the demand for craft beer is steadily growing.

However, the wastewater generated during the brewing process poses environmental challenges that need to be addressed responsibly.

This article explores the generation of brewery wastewater and the importance of implementing effective wastewater treatment measures to safeguard the environment.

Brewery Wastewater Generation

Maintaining high levels of hygiene and cleanliness is essential in the brewing process, as beer is a sensitive foodstuff prone to contamination by foreign bacteria or yeast cultures. To ensure hygiene, breweries use a significant amount of wash water, typically between 3.5 and 6 liters for every liter of beer produced.

The main sources of wastewater in breweries include cleaning of brewing utensils and production buildings, bottle cleaning, and pipe cleaning. The substances mixed into brewery wastewater include sugar, dyes, hop resins, husks, and cleaning chemicals.

Wastewater Categories in Breweries

Brewery wastewater can be categorized into three main types: process water, cooling water, and sanitary wastewater.

- Process Water: This type of wastewater is generated during the beer production process and arises from cleaning the brewing equipment, bottles, and pipelines. It typically contains high concentrations of organic substances, nitrogen, phosphorus, and cleaning chemicals.

- Cooling Water: Cooling the wort, a crucial step in beer production, requires water, which may contain metal concentrations but usually has low organic contamination.

- Sanitary Wastewater: Produced from toilets, washbasins, and showers, this type of wastewater contains residues of cleaning agents or soaps and is highly biodegradable.

Impact on the Environment

Untreated brewery wastewater can have severe environmental repercussions. Direct discharge of untreated wastewater into water bodies can lead to overfertilization due to its high organic and nutrient content.

This, in turn, promotes the exponential growth of algae, leading to reduced oxygen levels in the water and adverse effects on aquatic life. Moreover, organic substances can accumulate in the soil and contaminate groundwater, especially when the brewery is located near a well or spring.

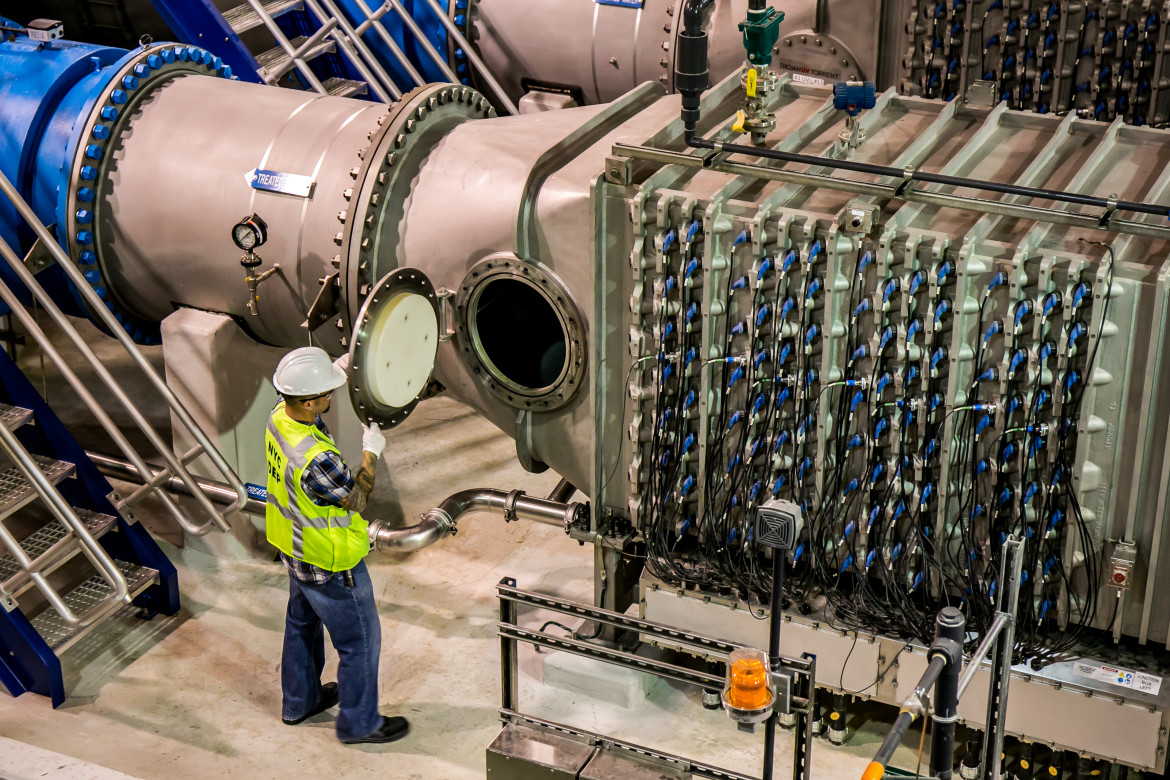

Importance of Wastewater Treatment

The treatment of brewery wastewater is a complex process, influenced by various brewing techniques and practices. An efficient treatment solution requires a thorough analysis of the wastewater’s composition to determine the most suitable treatment approach.

Implementing effective wastewater treatment not only safeguards the environment but also ensures compliance with discharge regulations and prevents potential harm to surrounding ecosystems.

Importance of Water Management in Brewery Wastewater Treatment

Effective water management is of paramount importance in brewery wastewater treatment. As the brewing industry continues to grow, it places a greater burden on water resources and wastewater treatment systems.

By implementing efficient water management practices, breweries can achieve several crucial objectives:

- Environmental Protection: Proper water management ensures that the wastewater generated during the brewing process is treated to remove harmful pollutants before discharge. This protects the environment from contamination, minimizing the negative impact on water bodies, aquatic life, and groundwater.

- Regulatory Compliance: Many regions have strict regulations and discharge standards for industrial wastewater. By managing water responsibly and adhering to these standards, breweries can avoid legal issues, fines, and reputational damage.

- Resource Conservation: Water is a valuable resource, and responsible water management helps breweries conserve this essential asset. By optimizing water usage and reducing wastewater generation, breweries can contribute to sustainable water practices.

- Operational Efficiency: Effective water management leads to improved operational efficiency within the brewery. Minimizing water usage and optimizing treatment processes can result in cost savings and increased productivity.

Advantages of Zeolite Filter Media over Sand Filters

In the context of brewery wastewater treatment, using zeolite as a filter media offers several advantages over traditional sand filters:

- Enhanced Contaminant Removal: Zeolite has a unique molecular structure that allows it to effectively trap and remove a wide range of contaminants, including heavy metals, ammonia, and certain organic compounds. This property makes zeolite highly effective in treating brewery wastewater, which often contains elevated levels of nitrogen and organic substances.

- Higher Filtration Efficiency: Zeolite filters have a higher specific surface area compared to sand filters. This increased surface area provides more active sites for adsorption and ion exchange, leading to better filtration efficiency and improved pollutant removal.

- Reduced Footprint: Zeolite filters can achieve the same level of filtration as sand filters with a smaller filter bed depth, resulting in a reduced overall footprint. This advantage is particularly valuable for microbreweries or urban breweries with limited space.

- pH Stabilization: Zeolite filter media can help stabilize the pH of the treated wastewater, preventing potential pH fluctuations that could hinder downstream treatment processes or negatively impact the receiving water bodies.

- Lower Backwash Water Requirements: Zeolite filters require less backwash water compared to sand filters due to their higher filtration efficiency. This results in reduced water usage during the backwashing process and contributes to overall water conservation efforts.

Water management plays a critical role in the sustainable and responsible operation of breweries. By adopting efficient wastewater treatment practices and optimizing water usage, breweries can minimize their environmental impact, adhere to regulatory requirements, and conserve valuable water resources.

Zeolite filter media, with its superior contaminant removal and filtration efficiency, offers a viable and advantageous alternative to traditional sand filters, helping breweries achieve higher treatment performance while minimizing their ecological footprint.